Manufacturing

The facilities of ITC Endoprint support a full production cycle, from manufacturing to finishing, cleaning and pre-sterilization preparation of implants. Thanks to their long-standing experience with additive manufacturing as well as processing components made of titanium and a diverse array of polymers, the company’s process engineers are able to create unique implants and auxiliary surgical instruments that would not be possible to make using conventional manufacturing methods.

The facilities of ITC Endoprint support a full production cycle, from manufacturing to finishing, cleaning and pre-sterilization preparation of implants. Thanks to their long-standing experience with additive manufacturing as well as processing components made of titanium and a diverse array of polymers, the company’s process engineers are able to create unique implants and auxiliary surgical instruments that would not be possible to make using conventional manufacturing methods.

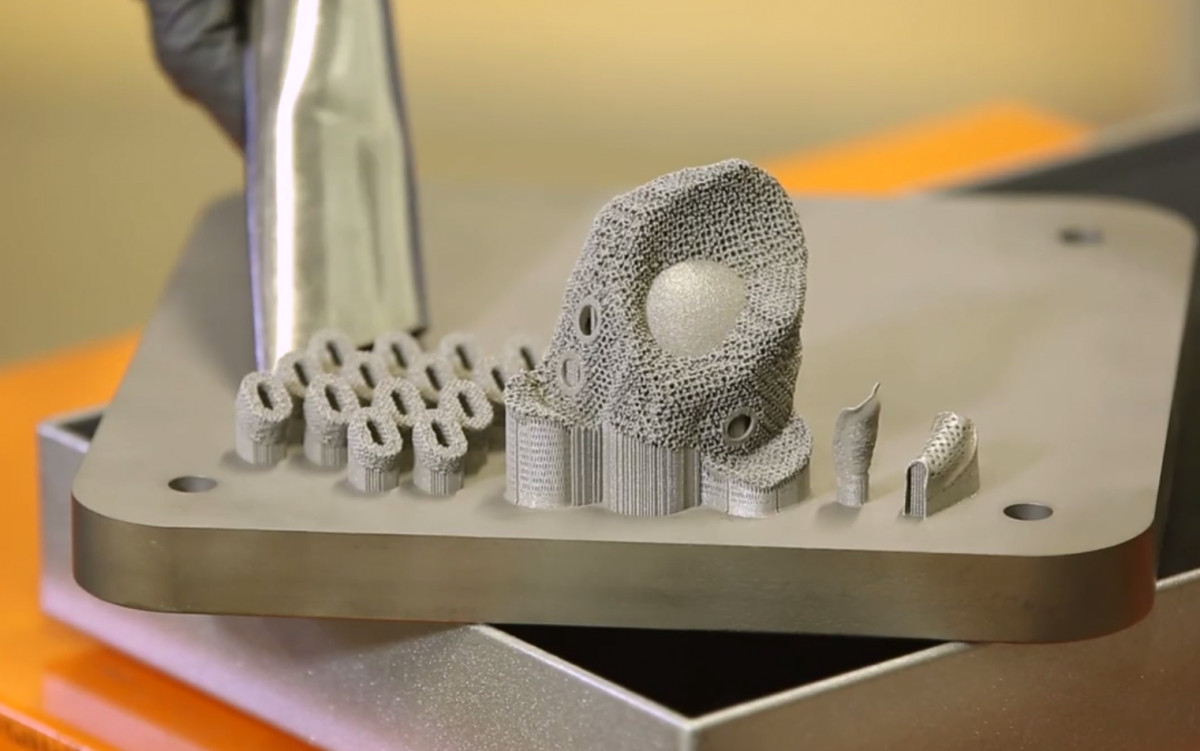

Our products are manufactured on a modern high-precision 3D printer that uses a titanium powder laser sintering technology. This piece of manufacturing equipment allows to create multiple types of surfaces with varying structure in the same product. With this technology we create implants with a porous structure similar to trabecular bone tissue which drastically improves osseointegration (connection between living bone and an implant) as proven by extensive research and numerous clinical trials.

Implants are built in an argon artificial atmosphere to prevent spontaneous combustion and preserve the technological properties of titanium, which is crucial for creating a high-quality medical device. Once the products are built in a 3D printer, they are sent to a furnace camera for heat treatment to eliminate internal stresses, thus further enhancing the implants’ durability.

When creating personalized implants, we exclusively use materials certified for medical applications – titanium alloy Ti6Al4V (Germany) conforms to GOST R ISO 5832-8-2018 (a Russian standard for surgical implants conforming to requirements set by the International Organization for Standardization) and has a European medical certification as well as a Russian Certificate of Conformity.

Every product goes through the procedures of finishing, cleaning and pre-sterilization preparation. The entire production cycle conforms to the ISO 13485 quality management system standard with quality control checks ensuring the compliance of our products’ quality to international standards.